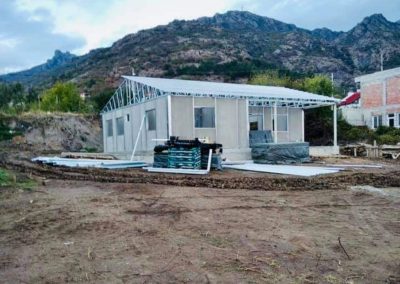

Prefabricated houses

GRAPHIC INFORMATION – SYSTEM DESCRIPTION

SUPPORT SYSTEM

The main support frame of the prefabricated house is composed of a galvanized profile made on a roll forming machine; rolling of “H” profiles of galvanized sheet with a roll forming machine (used for the production of support structures).

The horizontal load-bearing structures of the roof, which are made with a roll forming machine, are used to connect the supporting structures and strengthen the structure.

METALLIC STRUCTURE

The methodology for distributing the material of a prefabricated house is made using the Sap 2000 calculation method, and the structure is designed in the Autocad program and played as photos. The entire conveying system consists of special models of galvanized H, C, U profiles, manufactured on the roll forming machine.

PLAN of a manufactured home

The prefabricated structures are available in a width and length of 125 cm. The prefabricated structures are available in 4 different panel modulation.

The outer door panel (90kg) is the heaviest part, produced with a full wall panel, a window panel, a wall panel with a small window, and a door panel.

EXTERIOR WALLS

(Height: 2500/2800 / 3000mm; Density: 140/100 / 60mm) Press Panel

EXTERIOR SURFACE – 8 mm densely cemented chipboard (Betopan)

INTERNAL SURFACE – 8 mm cemented chipboard (Betopan)

COMBINED ELEMENTS – The entire roll forming machine for galvanizing is removed from the machine INSULATION 120/80/40 mm density 16 kg / m³ Polystyrene foam

WALL COMBINATION

Special connection elements and “H” profiles are combined with a special grip system made of pleated edges that will not rust from fogging.

THE CEILING

Coverage:

10mm thick plasterboard normal gap

Gypsum board wet gap with a thickness of 12mm

Combination elements – Electrostatically painted fasteners made of galvanized sheet

Insulation – Solid glass wool with a density of 80 mm (according to TSE standards)

ROOF COVER

Cladding: 0.50mm painted trapezoidal sheet

Support structure – The support system with quality S320 GD + Z, AZ Erdemir with number: 1322 is made of specially designed galvanized sheet profiles.

Longitudinal roof beams – Made of galvanized sheet metal using a roll forming machine (1.2 mm)

Eaves – Covered with a special twisted galvanized sheet of 30 cm wide.

PVC roof 150 mm, square type storm drain.

DOORS

Interior doors for prefab house with size 80 * 198cm, with metal frame, American type door, with left and right side on the handle.

Exterior doors: Steel door with size 90 * 198cm, steel door with size 90 * 250cm.

(According to TSE standards)

WINDOWS AND GLASSES for a prefab house

Window – 120 * 100 with dimensioned PVC windows

Small window – 60 * 40 with size PVC frame

Joinery: made of cold formed sheet metal with a thickness of 1.2 mm

Window profile width – 60 mm – 3 spotlights. Window glass – 4 + 12.5 + 4 mm, double

OUTSIDE

(TSE standards)

Metal part: two coats of primer and two coats of oil paint.

Inner side: two layers of plastic paint.

Prefabricated house roof – Two coats of plastic paint.

ELECTRICAL INSTALLATION

Cable wires – 3 * 2.5 according to Nym TSE standards.

Contacts and buttons (according to TSE)

Lighting: 2 * 40 fluorescent lighting.

Bathroom and toilet – Illuminated with the help of round light globes.

Above the door: There is a globe on the outer door.

BATHROOM INSTALLATION

(According to TSE standards for prefab house)

Drinking water pipes – PVC pipe

Sewage Pipes – PVC Pipe

Vitrification and hardware

TRANSITION

(for two and one story containers and prefab)

Enclosure – Special cast galvanized sheet finished panels formed together

Top Coating – Betopan with a density of 16mm

Suspended ceiling – Laminated gypsum board with a density of 12 mm

Insulation: glass wool with a density of 100 mm

Load: calculated at 400 kg / m2.

STAIRS

(for two and one story containers and prefab)

Casing – Of metallic structures made of box-type profiles.

Cover: concrete with a density of 16 mm

Painting: double coat of primer and double coat of oil paint

Prefabricated house railing – Profiled